Imagine a world without seals—not the adorable marine mammals, but the essential components that keep the machinery running smoothly. In engineering, hydraulic seals play a pivotal role in ensuring the efficiency and longevity of hydraulic systems. These humble yet ingenious devices are the unsung heroes behind the scenes, responsible for preventing leaks and maintaining pressure within hydraulic cylinders. Delve into the fascinating science behind these innovative seals, unraveling their technology and shedding light on their vital contributions.

Unveiling the Importance of These Seals

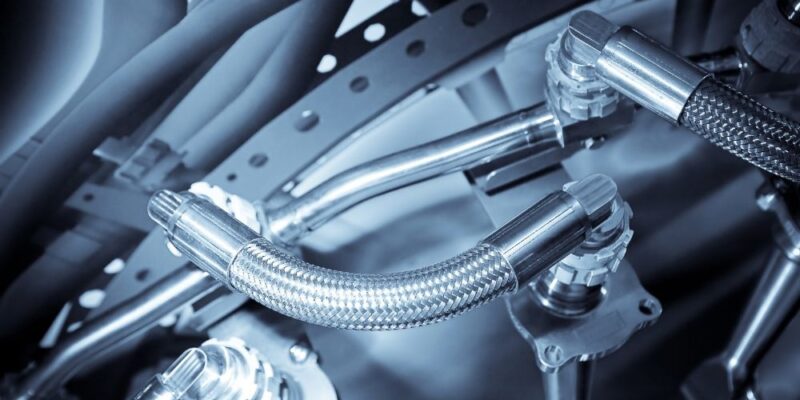

These seals are vital guardians of hydraulic systems, ensuring the efficient operation of various machinery and equipment. These seals act as barriers, preventing the escape of hydraulic fluid and the entry of contaminants into the system. By doing so, they maintain pressure and facilitate the smooth functioning of hydraulic cylinders, pistons, and valves.

Understanding Seals: Function and Types

Hydraulic seals can be classified into different types based on their design and application. Some common types include piston seals, rod seals, wiper seals, and wear rings. Each type serves a specific purpose: preventing fluid leakage, protecting against external contaminants, or guiding the piston within the cylinder. These seals are typically made from elastomeric or polymeric materials, chosen for their compatibility with hydraulic fluids and ability to withstand high pressures and temperatures.

Material Matters: Exploring Seal Materials and Their Properties

The choice of material for these seals is crucial for their performance and durability. Common materials include nitrile rubber, polyurethane, fluorocarbon, and silicone. Nitrile rubber seals are known for their excellent resistance to oil and fuel, while polyurethane seals offer high abrasion resistance. Fluorocarbon seals excel in extreme temperatures and harsh chemical environments. Due to their low toxicity and high flexibility, silicone seals find applications in the food and medical industries.

The Role of Design: Anatomy of a Hydraulic Seal

A hydraulic seal comprises several essential components that work together to achieve a reliable and effective seal. These components include the sealing lip, which comes into contact with the moving parts, and the energizer, which ensures proper sealing force. The design also incorporates backup, anti-extrusion, and wear rings to enhance the seal’s performance and lifespan.

Seal Installation: Best Practices for Optimal Performance

Proper installation of the seals is crucial for their optimal performance. The seals must be correctly sized and installed with the right amount of compression. Lubrication is also essential to reduce friction and enhance sealing efficiency. Following manufacturer guidelines and using specialized tools for installation can significantly contribute to the longevity of these seals.

Innovations in Hydraulic Seal Technology

Advancements in materials science and engineering have led to innovative hydraulic seal technologies. Self-lubricating seals, for example, reduce the need for external lubrication, enhancing convenience and reducing maintenance requirements. High-performance seals with improved resistance to extreme conditions and longer service life are also emerging, driven by ongoing research and development efforts.

The Future of The Seals: Advancements and Prospects

As technology advances, the future of these seals holds promising possibilities. With ongoing research and development, we can expect the emergence of seals that offer improved performance, enhanced durability, and increased efficiency. Integrating intelligent materials and sensor technologies may enable seals to provide real-time data on their condition, allowing for predictive maintenance and further optimization of hydraulic systems.

Conclusion

Hydraulic seals are the unsung heroes of hydraulic systems, ensuring the smooth operation of machinery and equipment across various industries. With their innovative designs, reliable materials, and meticulous installation, these seals contribute to hydraulic systems’ efficiency, safety, and longevity. As technology progresses, further advancements in hydraulic seal technology are expected, ushering in a new era of improved performance and reliability.

Comments